Meet the team: Ian Fleming

Ian Fleming, Gas Technical Trainer at EOGB, tells us about his experience in the industry throughout the years…

So where did it all begin?

Throughout my childhood, I always approached everything with a technical mind. I was inclined to pull apart, inspect and attempt to fix every faulty electronic item in the house.

In 1993, I left school and immediately started a gas apprenticeship with British Gas, where both my parents had worked. I gained all my qualifications and have worked in the industry ever since!

How did you become a gas trainer?

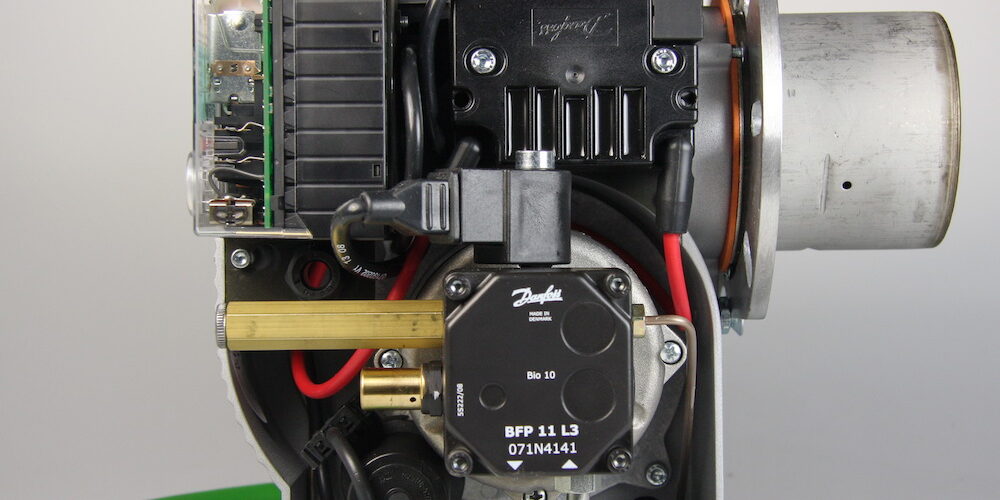

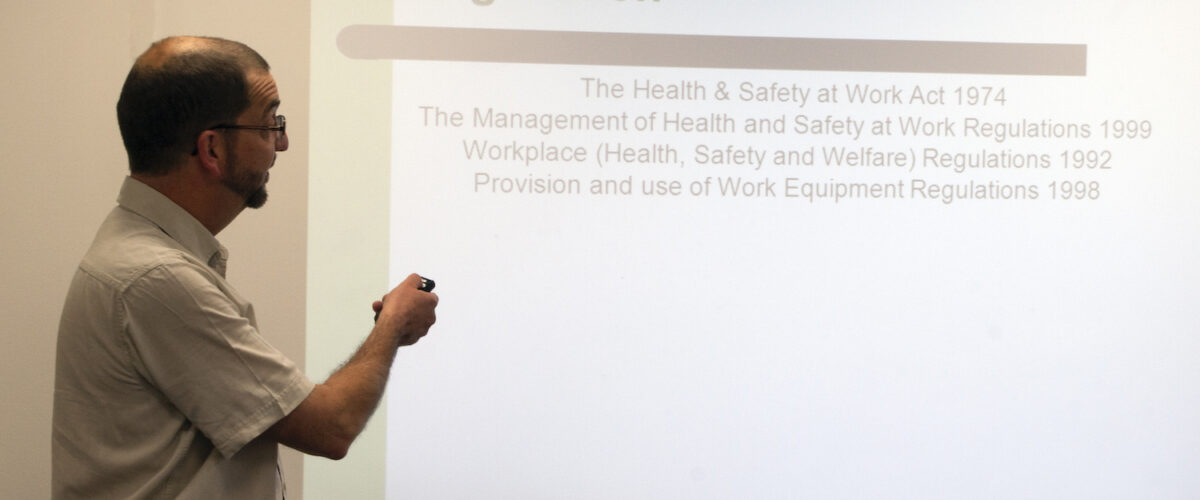

In 2002, after working in the industry for many years, I felt it was time to give back and begin training the next generation of engineers. In 2013 I met Martin Cooke, Technical Director at EOGB. I subsequently helped setup the company’s flagship gas training and assessment centre and have been working with EOGB ever since.

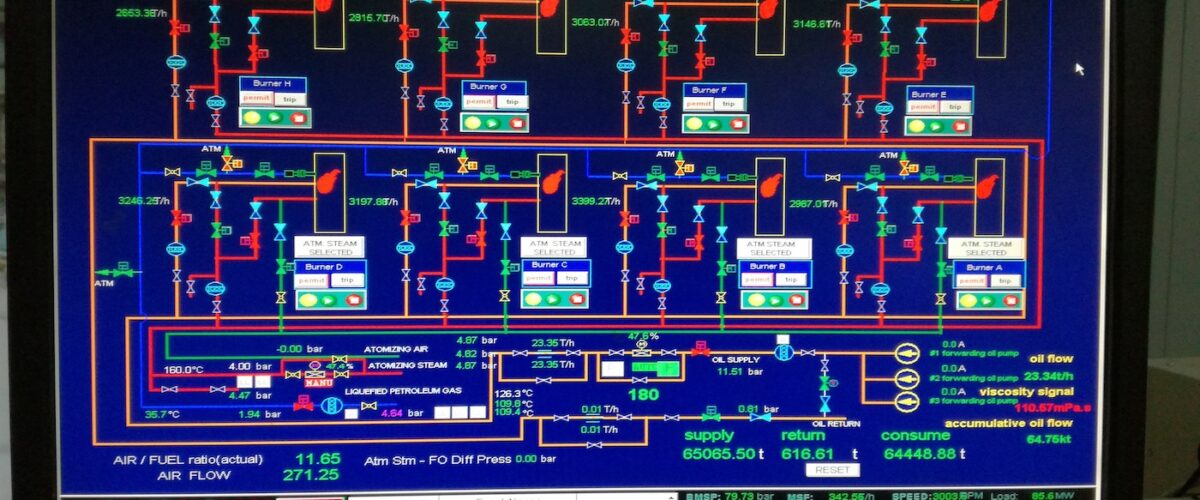

Alongside working as a gas trainer, I also work as an on-site gas safety auditor and an incident investigator, which keeps me very busy.

What’s the best advice you have been given throughout your career?

The best advice I’ve ever been given is simply to never stop learning. The day you wake up and don’t learn anything is the day you should start to think about new career options.

Luckily for me, the gas industry is always evolving, so there’s always more to learn. I’m currently completing a master’s degree in engineering with the Open University, which I am really enjoying.

What advice would you give to those thinking about a career in gas?

My advice would be to enrol onto a course and get stuck in, you definitely won’t regret it. Gaining qualifications will open the door to a variety of work environments and roles, so you’ll never have to settle for just one job.

What’s more, the industry offers plenty of opportunities for professional development and diversification, making it a lucrative career choice.

How do you relax after a hard day at work?

When I’m not studying for my master’s degree, you’ll find me in my workshop at home, where I am currently renovating a 1940’s gas iron.

I’m also a corporate sponsor of the British School’s Museum in Hitchin, which is home to the last Monitorial schoolroom in the world. In the near future, I hope to donate my renovated gas iron to the museum for display.

One final question, what’s your favourite book?

Believe it or not, I’ve never read a fiction novel in my life. However, I do enjoy reading technical manuals and guides, particularly the Haynes car manuals.

I remember reading my first Haynes manual back in the 1990s, when I passed my driving test and bought my first car – a Volkswagen Golf.